Japanese knives are renowned for their precision and sharpness, making them a favorite among both professional chefs and home cooks. When working with these fine knives, it's important to pair them with the right cutting board to protect their delicate edges and enhance their performance.

In this article, we'll explore various options, including plastic cutting boards, wooden boards such as end-grain boards and classic Hinoki Cypress wood, and synthetic materials like Hi-Soft (polyvinyl acetate), all-rubber boards such as Asahi rubber and Sani-tuff, and Hasegawa cutting boards (polyethylene with wood core). Each material has unique characteristics that can impact the longevity and performance of your Japanese knives. So, let's dive into the world of cutting boards and help you make an informed decision about which board best suits your needs.

Recommended Materials

Hinoki Cutting Boards

Hinoki wood, a type of cypress native to Japan, is a top choice for Japanese knife enthusiasts. It is, by far, one of the best woods for use with Japanese knives. These cutting boards are not only visually appealing with their pale, elegant appearance, but they also possess natural anti-bacterial properties that help inhibit the growth of bacteria. The soft and delicate nature of Hinoki wood is gentle on your knife's edge, reducing the chances of chipping or dulling the blades, making them an excellent cutting surface. Some hinoki cutting boards have a juice groove cut into the perimeter prevent spillage.

Hi-Soft (Polyvinyl acetate)

Hi-Soft cutting boards are very soft and designed specifically for Japanese knives. They provide a soft cutting surface that protects the knife's edge, making them a better choice for those who use their knives frequently. While the soft material reduces the impact on the knifes edge, it also creates some noticeable drag as you slice and the knife comes in contact with the board. The boards are easily cleaned with hot, soapy water but are not dishwasher safe. I have two Hi-Soft boards, in different sizes, and use the larger board for making sushi. The board works well when slicing through fresh fish, cucumber and roasted sushi nori seaweed.

There is, however, a downside to using such a soft cutting board. I recently used my smaller Hi-Soft board while cutting some Guanciale into ¼" pieces. Guanciale is similar to pancetta and can be very difficult to slice through. Slicing it required a fair amount of downward pressure that caused the knife blade to cut into the cutting board. The result was a ruined cutting board with a lot of little pieces of polyvinyl acetate (tear out) mixed in with my diced guanciale.

Hi-Soft cutting board - top view.

Hi-Soft cutting board - side view.

Hi-Soft cutting board with tear out damage.

Synthetic Rubber (Sani-Tuff and Asahi Rubber)

Synthetic rubber cutting boards, like Asahi rubber and Sani-Tuff, are made from a high-density rubber composite that is both resilient and gentle on knife edges. Asahi rubber cutting boards are made from an elastic polymer and Sani-tuff boards are made with a high-density rubber composite, both of which that absorb impact making them gentle on knives. Their non-porous surface is easy to clean and is resistant to moisture and bacteria, making them a sanitary choice for food preparation. These boards are gentle on the knife blade and come in different sizes.

Hasegawa Boards (Polyethylene with Wood Core)

Hasegawa brand cutting boards combine the durability of polyethylene with the stability of a wood core. This construction provides a sturdy surface, with lighter weight, making them a good option for use with Japanese knives. They are resistant to bacterial growth and are easy to clean, making them ideal for handling raw meat and other foods. They are less likely to warp or show knife marks, making them a practical choice for those who use their Japanese knives extensively.

Hasegawa boards come in a variety of sizes and surface hardness. My preferred Hasegawa board is the FSR model that is still soft, but harder than Hi-Soft boards and therefore less prone to tear out.

Hasegawa cutting board - top view.

Hasegawa cutting board - side view.

Materials to Avoid

Plastic Boards (Polyethylene)

Plastic or polyethylene cutting boards are a popular choice in professional kitchens due to their affordability, durability and ease of maintenance. While these boards are OK for most kitchens using German knives, they are not OK for use with Japanese knives. They are just too hard and will dull a Japanese knife fairly quickly.

Plastic cutting board - top view.

Plastic cutting board - side view.

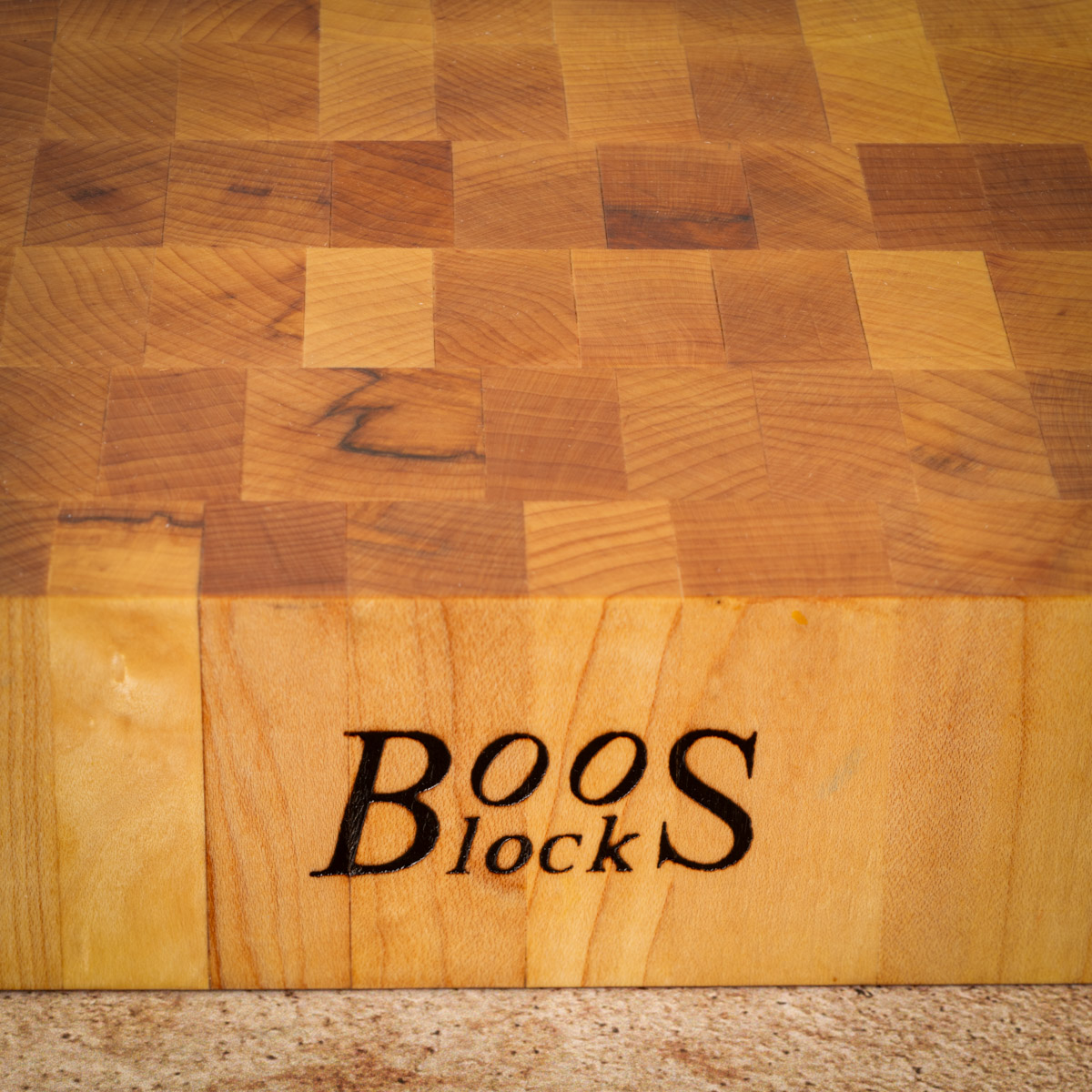

End-Grain Wood Boards

End-grain cutting boards, typically crafted from hardwoods like northern hard rock maple wood, cherry, or walnut, are known for their durability. They are designed by arranging wood pieces so that the end grain faces up, creating a sturdy and forgiving surface. This construction minimizes the impact on your knife's sharp edge and provides a self-healing property where the wood fibers naturally close up after each cut, prolonging both the knife and board's life. Unfortunately, they are not recommended for use with Japanese knives.

The problem with end-grain cutting boards is that the board may have adjacent blocks of wood with vastly different hardness. That means your knife edge will be subjected to differing levels of hardness across the board. Also, since these boards are made up of many pieces glued together, they are more prone to cracking and deformity. Once an end-grain board glue joint fails, the board should be discarded because there is no way to effectively clean the board once that happens.

End-grain cutting board - top view.

End-grain cutting board - side view.

Bamboo Boards

Bamboo cutting boards are best suited for use with German knives, but not Japanese knives. These cutting boards may be durable, lightweight, and have natural resistance to moisture, but they are too hard and will quickly dull a Japanese knife.

Bamboo cutting board - top view.

Bamboo cutting board - side view.

Maintenance Tips

To prolong the life of your cutting board, regardless of the material, clean it with a hot, damp cloth and mild detergent after each use. Never soak any of the boards in water. For Hinoki boards, apply food-grade mineral oil periodically to maintain its luster and prevent the wood from drying out.

Final Thoughts

Japanese knives are precision tools revered for their exceptional craftsmanship and they need to be used with the right cutting board. Choosing a good cutting board is essential for maintaining the sharpness and longevity of your blades.

When selecting the best cutting board for your Japanese knives, consider factors like material, maintenance and the type of food preparation you'll be doing. Whether you prefer the traditional feel of Hinoki wood, the softness of Hi-Soft (polyvinyl acetate), the resilience of rubber boards like Asahi rubber and Sani-tuff, or the durability of Hasegawa polyethylene with a wood core, your choice will impact your experience using your Japanese knives. You may find that you need more than one board depending on what you are cutting. For example, you may need a soft board for preparing sushi and a medium-soft board for slicing vegetables and meat. The right cutting board is not just another kitchen tool, it's an investment in the longevity and performance of your Japanese knives.

Leave a Reply